Barbershop History

Barbershop Origins

Barbershops have a long history dating back to as early as 296 B.C. in Greece where Greek men would go to have their hair and beards at the local marketplace and catch up on the latest news and gossip. Throughout the centuries, the role of the barbershop evolved to include medical services.

By the mid-1500s the skills of barbers was recognized in the medical world; due to the requirement that barbers have advanced coordination and fine motor skills, and the fact that barbers used tools like scissors, knives, and razors, their duties began to overlap with medicine. This led to the emergence of barber-surgeons and barber-dentists in the mid-1600s. Barbers began performing minor surgeries, pulling teeth, and applying leeches along with cutting hair and beards. As advances in medicine and surgery surged in the early and mid-1800s this practice ended and barbers focused solely on cutting and styling men’s hair.

So why are barber’s poles red and white? The poles represent bloodletting with origins from the times of barber-surgeons. The red represents blood and the white bandages. The pole itself symbolized the stick a patient would hold and squeeze to make their veins protrude in preparation for the bloodletting.

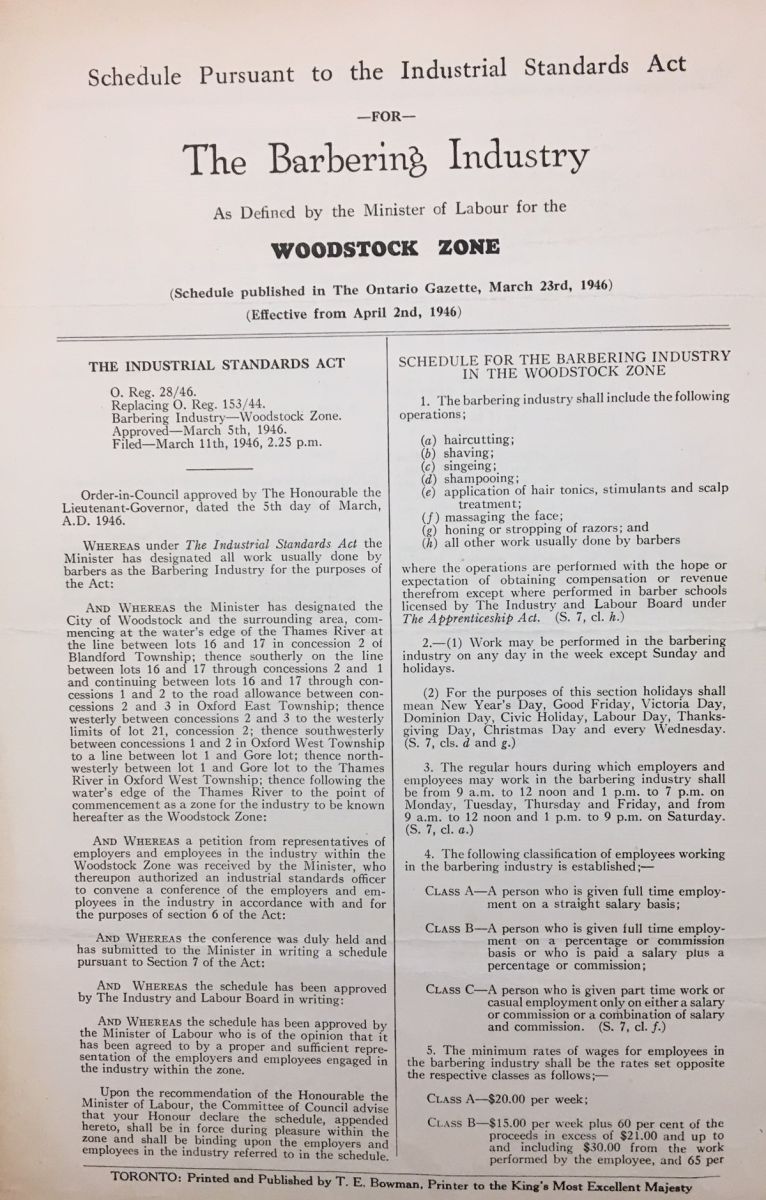

Schedule Pursuant to the Industrial Standards Act for The Barbering Industry - As defined by the Minister of Labour for the Woodstock Zone, March 23 1946 (Oxford County Archives). This schedule provides insight into the barbering industry in the 1940s. Barbershops were required to include the following operations: haircutting, shaving, singeing, shampooing, application of hair tonics, stimulants and scalp treatment, massaging the face, honing or stropping of razors, etc. Full-time barbershop employees were to be paid $20.00 a week. The price of an adult haircut was 40 cents, a child’s haircut 25 cents, and a shave was 25 cents. The average cost of a shave in the late 1800s was 3 cents. Today the average price for a shave at the barber is $20.

The Tools of the Trade

A Selection of Three Straight Razors

Beachville District Museum Collection

Photo credit: Sidney Hicks

Early grooming razors were basic shells or hefty, iron devices that resembled small hatchets. By the seventeenth century the straight razor, or cut-throat razor, was introduced. These razors consisted of blades usually made of sharpened silver steel that were protected by guards, or “scales.” The scales of straight razors were made of a variety of materials, including ivory, horn, wood, bone, shell or cellulite. Although they resemble a handle, most practiced shavers hold the blade just above the pivot pin, at a spot called the “tang”. The scales, then, are used to help balance the blade when shaving.

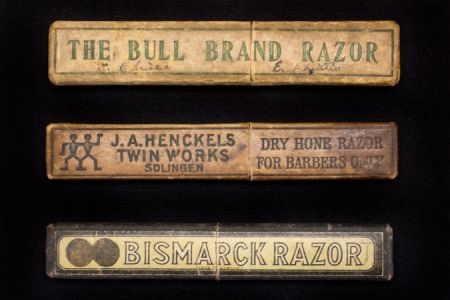

Coffin-Style Razor Boxes

Beachville District Museum Collection

Photo credit: Sidney Hicks

Straight razors were not easily wielded. They were more often the tools of trained barbers because, without skill, they could cause injury. Barbers have always offered a range of services; early barbers not only cut hair and shaved customers, they also acted as wig-makers, surgeons and dentists. By the nineteenth century, however, shaving became the mainstay of these tradesmen. High-end, professional razors were often manufactured in famous cutlery towns such as Sheffield, England and Solingen, Germany. J.A. Henckels and Bismarck were German brands both made in the “City of Blades” from high-quality, Solingen steel. The Solingen name is protected through the Solingen Decree (1938), which guards against fakes and misuse of the trademark. These classic, coffin-style straight-razor cases were made of cardboard in two parts. They often indicate where razors are from and who they are for (i.e. “Barbers only”).

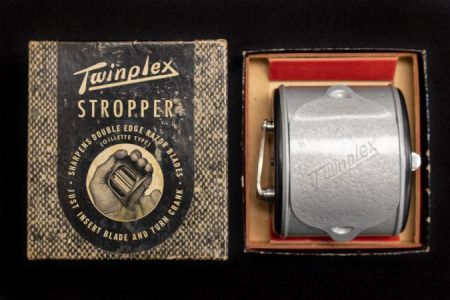

Strop for Sharpening Razor Blades

Norwich and District Museum

(Text below written by Beachville District Museum)

Barbers were trained to maintain a sharp blade through activities such as honing and stropping. Stropping involved drawing a razor over a strip of leather or canvas to keep it sharp and polished for shaving. With proper maintenance, a straight razor could be used everyday for well over a lifetime. Strops came in many forms, from conventional hanging strops to handheld paddle strops or loom strops.

Hone Stones

Beachville District Museum Collection

Photo credit: Sidney Hicks

In contrast to stropping, honing was only performed a few times a year to preserve a blade. The razor’s edge was pushed along the length of a whetstone or hone stone, flipped and pulled back. This repetitive motion removed steel to form a new edge on the blade. Hone stones come in different sizes and colours and are usually mined for in whetstone quarries. Natural stones like novaculite, fine-grained sandstones or garnet rocks are graded by their density. Some appear translucent, while others are completely opaque. These stones can either be lubricated with oil or water; those lubricated with oil are called oilstones and those lubricated with water are water stones. All are flat and finely graded. They must be kept free of dust and debris to function properly.

Safety Razors

Beachville District Museum Collection

Photo credit: Sidney Hicks

A safety razor is a razor with a guard beneath the blade edge. One of the most common versions of this razor is referred to as a hoe-type safety razor (or rake-type). These hoe-type razors were patented in Europe in the second half of the nineteenth century and became familiar to U.S. markets through the Diamond Safety Razor Company, established in 1885. Hoe-type safety razors have their blade and guards at a right angle to their handle and usually boast both removable blades and handles. The safety razor made shaving much less daunting for those who had never confidently taken up the straight razor. The Valet Auto Strop Safety Razor was made in Canada and was manufactured between 1921 and 1946 (right). The Gillette Safety Razor Company was worth an impressive $200,000,000 in 1927, having capitalized on the desire for an accessible razor easily maintained. The Schick Injector Razor (left) was produced starting in 1926.

Gillette 195 Adjustable Safety Razor

Beachville District Museum Collection

Photo credit: Sidney Hicks

This “Gillette Adjustable” razor set includes a plastic case, a set of Super Blue Blades and a hoe-type, “Fatboy” safety razor made between 1958 and 1962. The original retail cost of this razor would have been set at $1.95, which it why it was officially referred to as Gillette’s 195 razor. At the juncture between the blade and the handle, this razor featured a micrometer dial with the numbers engraved from 1 to 9. The numbers represented settings from the lightest to the heaviest beard. Super Blue Blades were introduced in 1959 and were silicone-coated carbon-steel blades. They were initially invented by Meyer Shnitzler. The Fatboy was one of Gillette’s most successful razors on the market through the second half of the twentieth century.

Shave Brushes

Beachville District Museum Collection

Photo credit: Sidney Hicks

Washing and lathering the face with soap are two important steps in preparing for a shave. Shaving brushes were invented in the eighteenth century and had course bristles made of nylon, boar hair, horsehair or badger hair. They were used to mix soap into a thick lather, loosen facial hairs and exfoliate the face. Large shave brushes with longer handles (like the one shown on the right) were fixtures in barbershops, while smaller ones (like that on the left) were common at home. The bases of these brush handles were usually flat and large so that the tools could stand upright to dry. When shaving foams were developed, these brushes became somewhat obsolete.

Shaving Mug

Beachville District Museum Collection

Photo credit: Sidney Hicks

Before shaving foams appeared on the market, shaving mugs constituted a key shaving tool. Whether shaving from home or paying for a wet shave at a barbershop, most men during the Victorian Era owned their own mug. This shaving mug was likely produced in Europe and imported to Canada before being customized for D.A. Boyle. Shaving mugs were sold by barbers and were often personalized with either hand-painted decorations or an individual’s name. They were kept on mug racks until the customer visited. A bar of soap was placed in the vessel and was brushed into a lather. Mugs were also individualized as a measure for public hygiene. They were introduced to prevent the spread of rashes caused by “barber’s itch.” Unfortunately, the fungus that caused the itch was transmitted on razors and new sterilization methods for metallic implements had to be devised.